WENZ The specialist for plastic peripherical technologies

About us

WENZ Kunststoff GmbH & Co. KG has been involved in plastics peripheral technology for 25 years. The technical focus is on mold tempering and drying of plastic resin with particular attention to optimize all parameters, thereby protecting the environment and minimizing the CO2 footprint. Originally started as a representative of tempering technology for company Regloplas, the gathered know-how has managed the development to a company which can meet any technical challenge.

WENZ is vision

The know how of WENZ gives them the power for developing new technologies like the Cycletemp Vario, Impuls and flow an the qip dryer, and a lot of new products, which are patented. The coupling station, which is available as a coded or uncoded system or the WeCo gravimetry, which has the highest level of accurance, are also developed by WENZ.

The technologies save money and the environment – they are green, because they save 90% CO2 emmission, up to 80% energy and up to 85% compressed air.

WENZ is flexibility & sustainability

Project planning, engineering and construction of conveying and drying systems for plastics – all at the cutting edge of technology that is signifacant benefit for our customers. The consequence of the technological know-how are cooperations with well known, globally operating companies. WENZ has got a strong relatiopship to the medium-sized companies – but they have the flexibility to be a reliable partner for companies of all sizes.

With the Retrofit of central material systems – WENZ is able to improve the performance and save a lot of energy when the customer doesn‘t want to invest money in a new central material handling system.

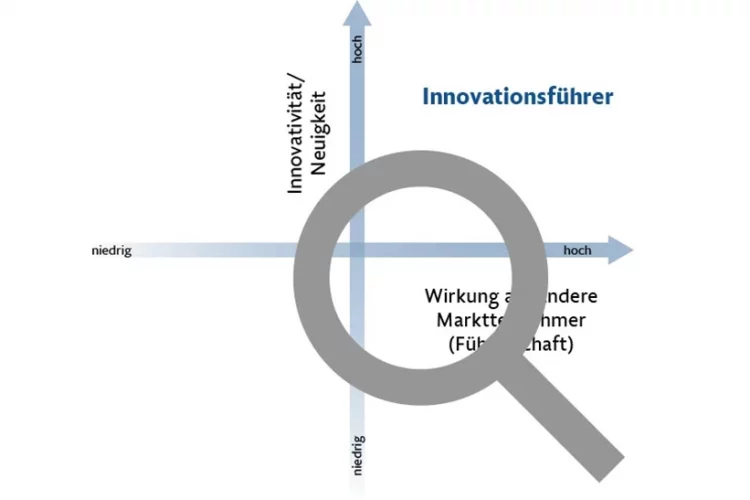

WENZ is innovation

The drying technology and eight other patents are the proof for the innovative power of WENZ.

WENZ‘ Service = customer‘s advantages

All in one: The planning of projects, innovations , machines for special needs in the temperature control, talkob and mouldpro couplings, multicouplings and hoses. manifolds, flowmeters and a lot of other products for the injection moulding machines. One partner for many businesses.